Publications

2025

-

Data-driven insights for enhanced cellulose conversion to 5-hydroxymethylfurfural using machine learningYanming Qiao, Ehsan Kargaran, Hao Ji, and 3 more authorsBioresource Technology, 2025

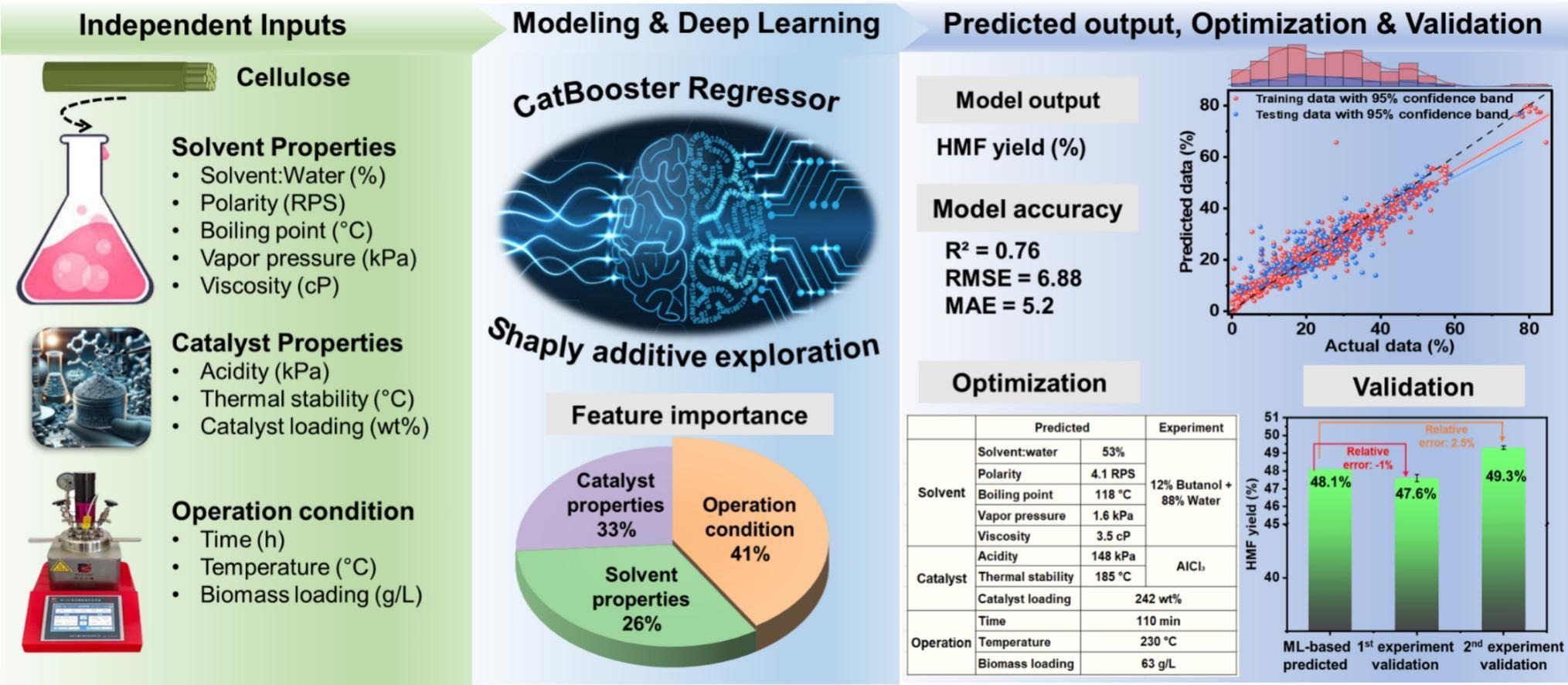

Data-driven insights for enhanced cellulose conversion to 5-hydroxymethylfurfural using machine learningYanming Qiao, Ehsan Kargaran, Hao Ji, and 3 more authorsBioresource Technology, 2025Converting cellulose into 5-Hydroxymethylfurfural (HMF) provides a promising strategy for creating bio-based chemicals, offering sustainable alternatives to petroleum-based materials in polymers, biofuels, and pharmaceuticals. However, the efficient production of HMF from cellulose is challenged by the complex interplay of numerous operational variables. This study develops a machine learning (ML) model to optimize HMF production and conducts a feature importance analysis to identify the key factors affecting HMF yield. Additionally, a Bayesian optimization is employed for multi-objective optimization aimed at maximizing HMF yield. A comprehensive dataset, sourced from existing literature, was subjected to statistical analysis to elucidate the influence of each factor on HMF production. Among the eight models evaluated, the CatBoost Regressor emerged as the most effective, delivering robust predictive performance with R2 of 0.76 during testing and exhibiting low RMSE (4.72) and MAE (5.2) values. Feature importance analysis revealed that operational conditions, particularly time and temperature, were the most significant, accounting for 41.0% of the variability, followed by catalyst properties at 33.0% and solvent properties at 26.0%. The ML-based optimization achieved an HMF yield of 48.1%, with relative errors of −1% and 2.5% in the first (47.6%) and second (49.3%) runs of experimental validation, respectively. This research showcases ML’s ability to address challenges in cellulose-to-HMF conversion, offering insights for optimizing production and advancing sustainable manufacturing.

2024

-

A Practical Machine Learning Approach for Predicting the Quality of 3D (Bio)Printed ScaffoldsSaeed Rafieyan, Elham Ansari, and Ebrahim Vasheghani-FarahaniBiofabrication, 2024

A Practical Machine Learning Approach for Predicting the Quality of 3D (Bio)Printed ScaffoldsSaeed Rafieyan, Elham Ansari, and Ebrahim Vasheghani-FarahaniBiofabrication, 20243D (Bio)printing is a highly effective method for fabricating tissue engineering scaffolds, renowned for their exceptional precision and control. Artificial intelligence (AI) has become a crucial technology in this field, capable of learning and replicating complex patterns that surpass human capabilities. However, the integration of AI in tissue engineering is often hampered by the lack of comprehensive and reliable data. This study addresses these challenges by providing one of the most extensive datasets on 3D-printed scaffolds. It provides the most comprehensive open-source dataset and employs various AI techniques, from unsupervised to supervised learning. This dataset includes detailed information on 1,171 scaffolds, featuring a variety of biomaterials and concentrations—including 60 biomaterials such as natural and synthesized biomaterials, crosslinkers, enzymes, etc.—along with 49 cell lines, cell densities, and different printing conditions. We used over 40 machine learning and deep learning algorithms, tuning their hyperparameters to reveal hidden patterns and predict cell response, printability, and scaffold quality. The clustering analysis using KMeans identified five distinct ones. In classification tasks, algorithms such as XGBoost, Gradient Boosting, Extra Trees Classifier, Random Forest Classifier, and LightGBM demonstrated superior performance, achieving higher accuracy and F1 scores. A fully connected neural network with six hidden layers from scratch was developed, precisely tuning its hyperparameters for accurate predictions. To promote future research, the developed dataset and the associated code are publicly available on www.github.com/saeedrafieyan/MLATE.

-

Acetone-butanol-ethanol fermentation products recovery: Challenges and opportunitiesSaeed Rafieyan, Mohammad Amin Boojari, Ali Setayeshnia, and 4 more authorsChemical Engineering Research and Design, 2024

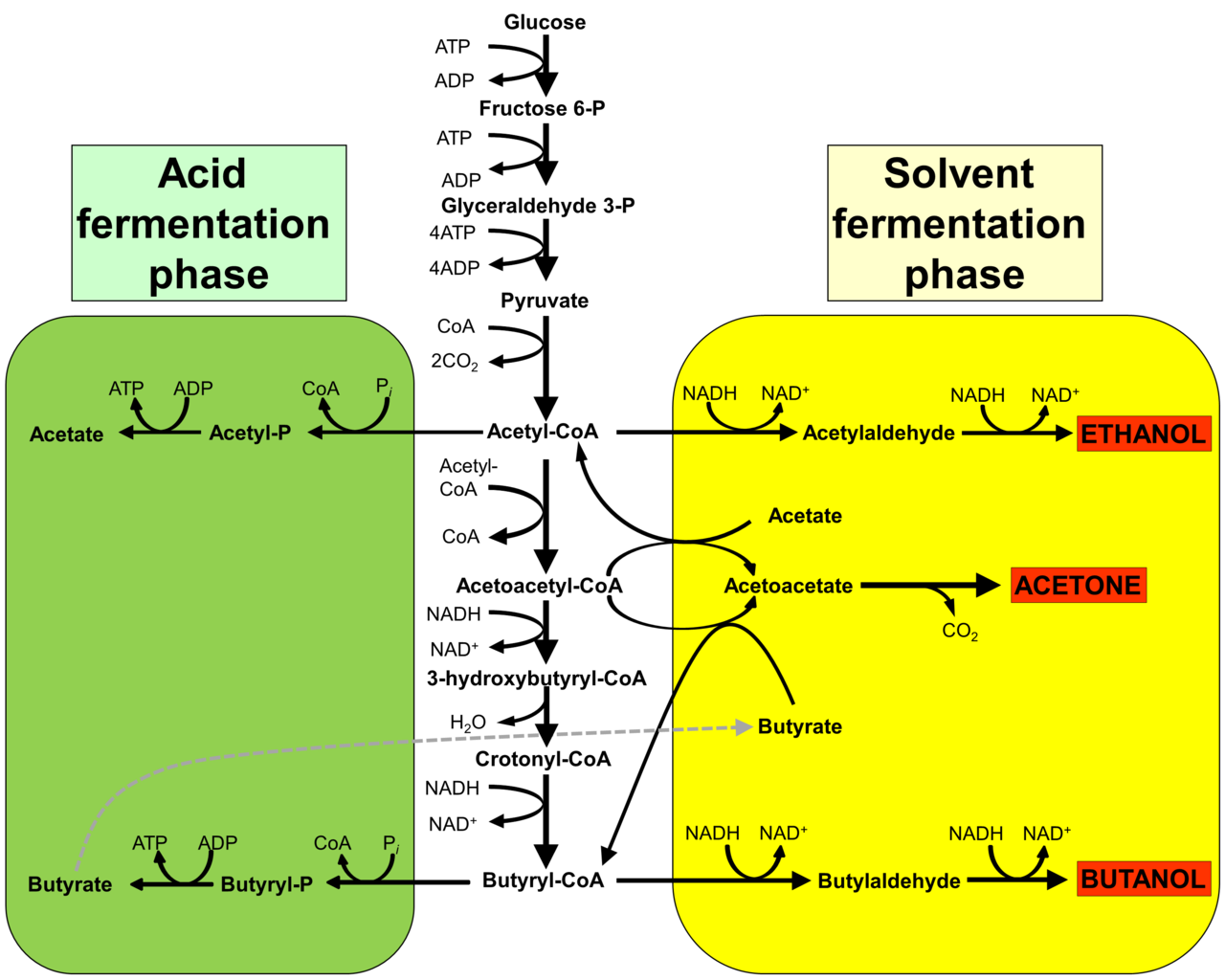

Acetone-butanol-ethanol fermentation products recovery: Challenges and opportunitiesSaeed Rafieyan, Mohammad Amin Boojari, Ali Setayeshnia, and 4 more authorsChemical Engineering Research and Design, 2024Nowadays, global warming is one of the most significant concerns in modern societies, which entails considerable costs to the environment, health, economy, etc. Fossil fuels play an essential role in this phenomenon and finding an alternative for them has been the research topic for the past few decades. Among the array of options available, biofuel stands out as a highly effective and environmentally sustainable alternative. Biobutanol presents properties like high heating value, low volatility, high viscosity, and low corrosion. Additionally, it is a much safer option for use, and its ability to blend with gasoline and other fuels turns it into a suitable and promising renewable alternative. Biobutanol can be produced from the agricultural industry’s residues by the acetone-butanol-ethanol (ABE) fermentation process. The separation and purification of biobutanol from the fermentation broth account for 40 % of the plant budget, which is notable. Various separation techniques like liquid-liquid extraction, membrane perstraction, gas stripping, vacuum flash, membrane pervaporation, thermopervaporation, reverse osmosis, adsorption, etc., are applied. A befitting separation method must produce sufficient butanol concentration in the output and reduce the final product’s cost so biobutanol can compete economically with other fuels. This work reviewed the existing processes for the separation and purification of butanol from ABE fermentation, including advanced methods. All methods will be discussed in detail considering environmental and economic parameters and each technique’s superiors and challenges.

2023

-

MLATE: Machine learning for predicting cell behavior on cardiac tissue engineering scaffoldsSaeed Rafieyan, Ebrahim Vasheghani-Farahani, Nafiseh Baheiraei, and 1 more authorComputers in Biology and Medicine, 2023

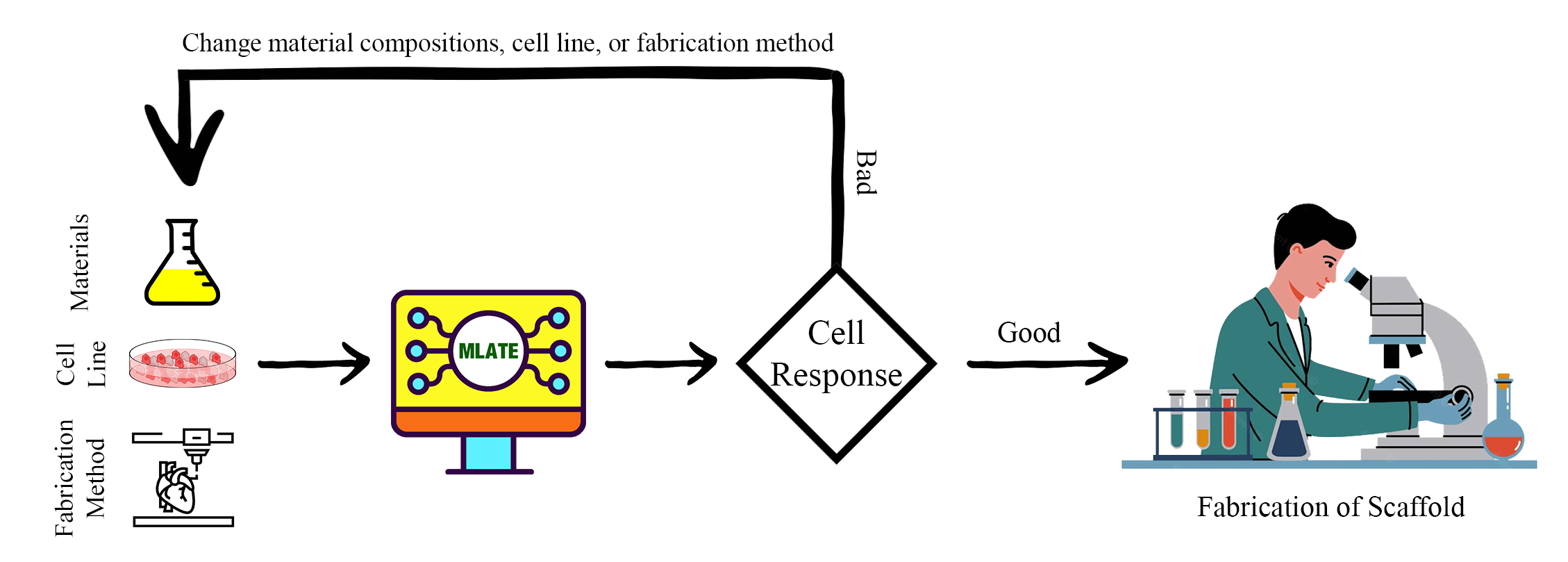

MLATE: Machine learning for predicting cell behavior on cardiac tissue engineering scaffoldsSaeed Rafieyan, Ebrahim Vasheghani-Farahani, Nafiseh Baheiraei, and 1 more authorComputers in Biology and Medicine, 2023Cardiovascular disease is one of the leading causes of mortality worldwide and is responsible for millions of deaths annually. One of the most promising approaches to deal with this problem, which has spread recently, is cardiac tissue engineering (CTE). Many researchers have tried developing scaffolds with different materials, cell lines, and fabrication methods to help regenerate heart tissue. Machine learning (ML) is one of the hottest topics in science and technology, revolutionizing many fields and changing our perspective on solving problems. As a result of using ML, some scientific issues have been resolved, including protein-folding, a challenging problem in biology that remained unsolved for 50 years. However, it is not well addressed in tissue engineering. An AI-based software was developed by our group called MLATE (Machine Learning Applications in Tissue Engineering) to tackle tissue engineering challenges, which highly depend on conducting costly and time-consuming experiments. For the first time, to the best of our knowledge, a CTE scaffold dataset was created by collecting specifications from the literature, including different materials, cell lines, and fabrication methods commonly used in CTE scaffold development. These specifications were used as variables in the study. Then, the CTE scaffolds were rated based on cell behaviors such as cell viability, growth, proliferation, and differentiation on the scaffold on a scale of 0–3. These ratings were considered a function of the variables in the gathered dataset. It should be stated that this study was merely based on information available in the literature. Then, twenty-eight ML algorithms were applied to determine the most effective one for predicting cell behavior on CTE scaffolds fabricated by different materials, compositions, and methods. The results indicated the high performance of XGBoost with an accuracy of 87%. Also, by implementing ensemble learning algorithms and using five algorithms with the best performance, an accuracy of 93% with the AdaBoost Classifier and Voting Classifier was achieved. Finally, the open-source software developed in this study was made available for everyone by publishing the best model along with a step-by-step guide to using it online at: https://github.com/saeedrafieyan/MLATE.

2022

-

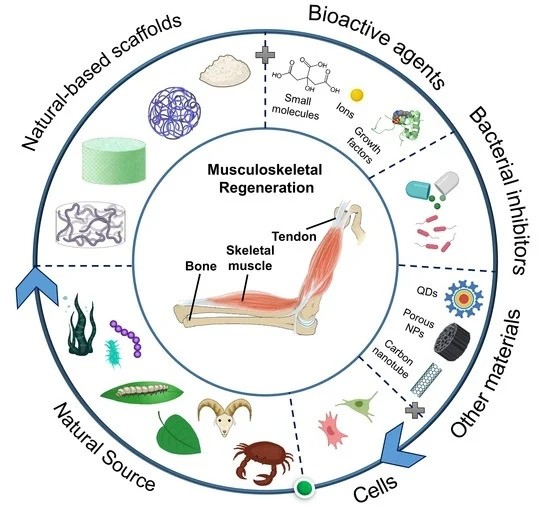

A Review of Recent Advances in Natural Polymer-Based Scaffolds for Musculoskeletal Tissue EngineeringJingzhi Fan, Keyvan Abedi-Dorcheh, Asma Sadat Vaziri, and 8 more authorsPolymers, 2022

A Review of Recent Advances in Natural Polymer-Based Scaffolds for Musculoskeletal Tissue EngineeringJingzhi Fan, Keyvan Abedi-Dorcheh, Asma Sadat Vaziri, and 8 more authorsPolymers, 2022The musculoskeletal (MS) system consists of bone, cartilage, tendon, ligament, and skeletal muscle, which forms the basic framework of the human body. This system plays a vital role in appropriate body functions, including movement, the protection of internal organs, support, hematopoiesis, and postural stability. Therefore, it is understandable that the damage or loss of MS tissues significantly reduces the quality of life and limits mobility. Tissue engineering and its applications in the healthcare industry have been rapidly growing over the past few decades. Tissue engineering has made significant contributions toward developing new therapeutic strategies for the treatment of MS defects and relevant disease. Among various biomaterials used for tissue engineering, natural polymers offer superior properties that promote optimal cell interaction and desired biological function. Natural polymers have similarity with the native ECM, including enzymatic degradation, bio-resorb and non-toxic degradation products, ability to conjugate with various agents, and high chemical versatility, biocompatibility, and bioactivity that promote optimal cell interaction and desired biological functions. This review summarizes recent advances in applying natural-based scaffolds for musculoskeletal tissue engineering.

2020

-

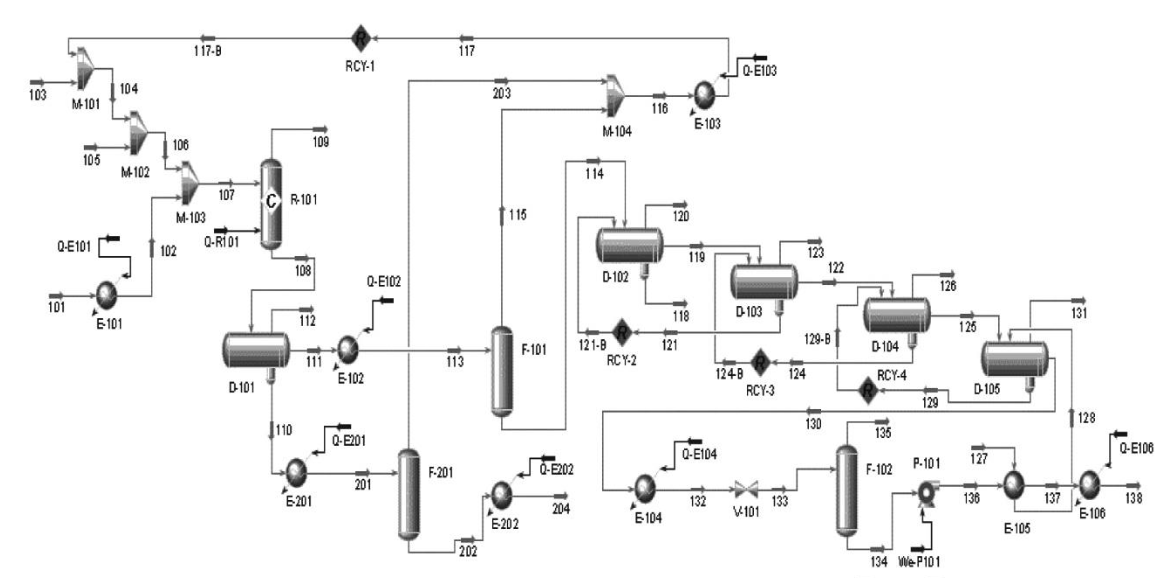

Process Simulation of Biodiesel Production from Soybean Oil with Aspen HYSYS: A Comparative Study of two different processesSaeed Rafieyan, and Ahamd BayatIn Proceedings of the 11th International Chemical Engineering Congress & Exhibition, Fouman, Iran , 2020

Process Simulation of Biodiesel Production from Soybean Oil with Aspen HYSYS: A Comparative Study of two different processesSaeed Rafieyan, and Ahamd BayatIn Proceedings of the 11th International Chemical Engineering Congress & Exhibition, Fouman, Iran , 2020Biodiesel is one of the most promising green fuels at present which can be easily obtained from various vegetable oils/animal fats and even waste cooking oils. In recent years, researchers have investigated a lot about biodiesel production processes. In order to produce biodiesel in an industrial scale and optimize the process, it’s needed firstly to simulate the production process to obtain information consistent with real data. In this respect, the vegetable oil fatty acid components (as a feedstock) were defined in detail. Afterward, two different processes suggested in the literature for biodiesel production were compared in terms of resource consumption and biodiesel yield.